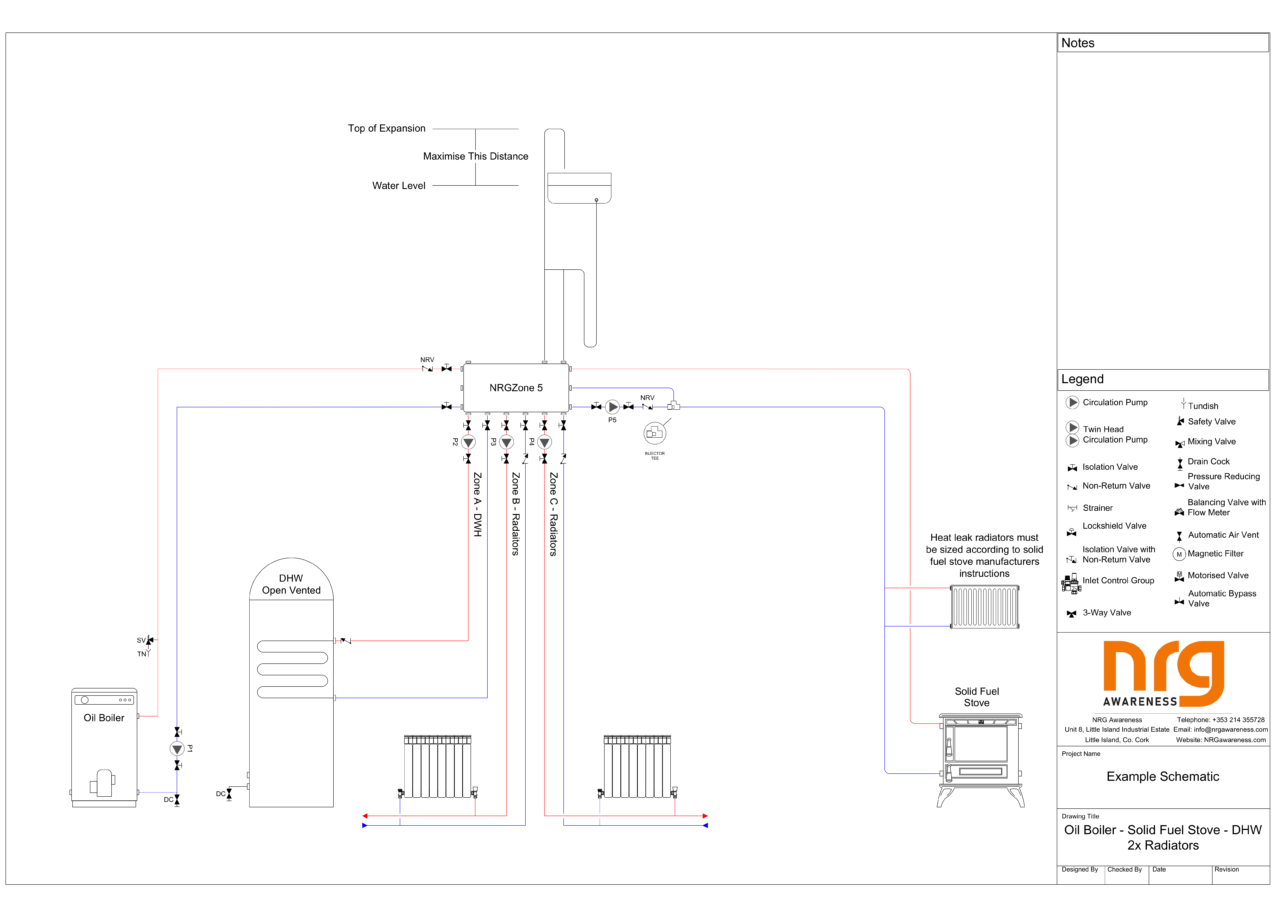

Oil Boiler – Solid Fuel Stove – DHW – 2x Radiators

This schematic shows an open-vented heating system with an oil boiler, a solid fuel stove, a DHW cylinder and two radiator zones. The DHW cylinder has a non-return valve on the flow into the coil instead of on the return like the heating zones, this is to prevent heat drifting from the cylinder, through the coil and up into the NRG Zone when the zone is not on. The solid fuel stove has an open gravity circuit rising up from the stove, into the NRG Zone, through its fully open bypass, the injector tee and back down to the stove. There is a heat leak radiator on the return pipe to dissipate any excess heat from the stove in the event of a power outage. This primary circuit is crucial for the safety of the system and there can be no valves or restriction on it. There is a parallel return from the NRG Zone to the stove with a pump and the injector tee. When the stove is up to temperature, this pump will turn on and fire the water back to the stove through the injector tee. The injector tee will increase the flow rate in both branches entering it and the flow rate through the stove will increase and more energy will be delivered to the heating system.

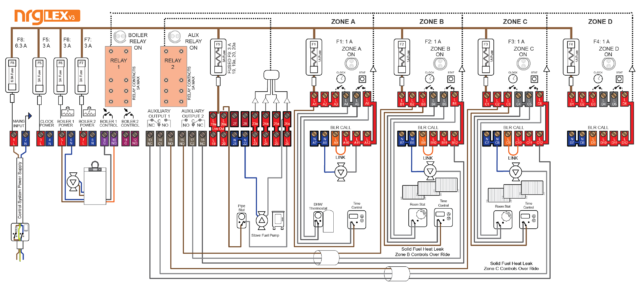

The system is wired in such a way that whenever the solid fuel stove is up to temperature, the two heating zones acts as heat leak zones and will turn on to dissipate the heat from the stove and prevent it from over heating. When the heating zones act as heat leaks the zone controls are bypassed and the oil boiler will not fire. The DHW zone will continue to work as normal with its time and temperature controls. The oil boiler will fire when any of the zones controls are calling for heat. If the stove is on and there is a call for heat, the appliances will work together to heat the system.