HOME

HOME

A hybrid heating system is an integrated system that combines a heat pump with a traditional boiler, such as an oil, gas, or biomass boiler. This combination harnesses the benefits of both low-temperature heat pumps and high-temperature boilers. The heat pump typically operates during milder weather conditions when its Coefficient of Performance (COP) is high, leading to greater energy savings. As temperatures drop, making it less efficient or economical for the heat pump to operate, the traditional boiler takes over to provide the necessary energy.

In designing a hybrid system, ensuring that the heat pump and boiler do not operate simultaneously is crucial. The high-temperature water from the boiler could cause the lower-temperature heat pump to shut down due to a significant temperature differential.

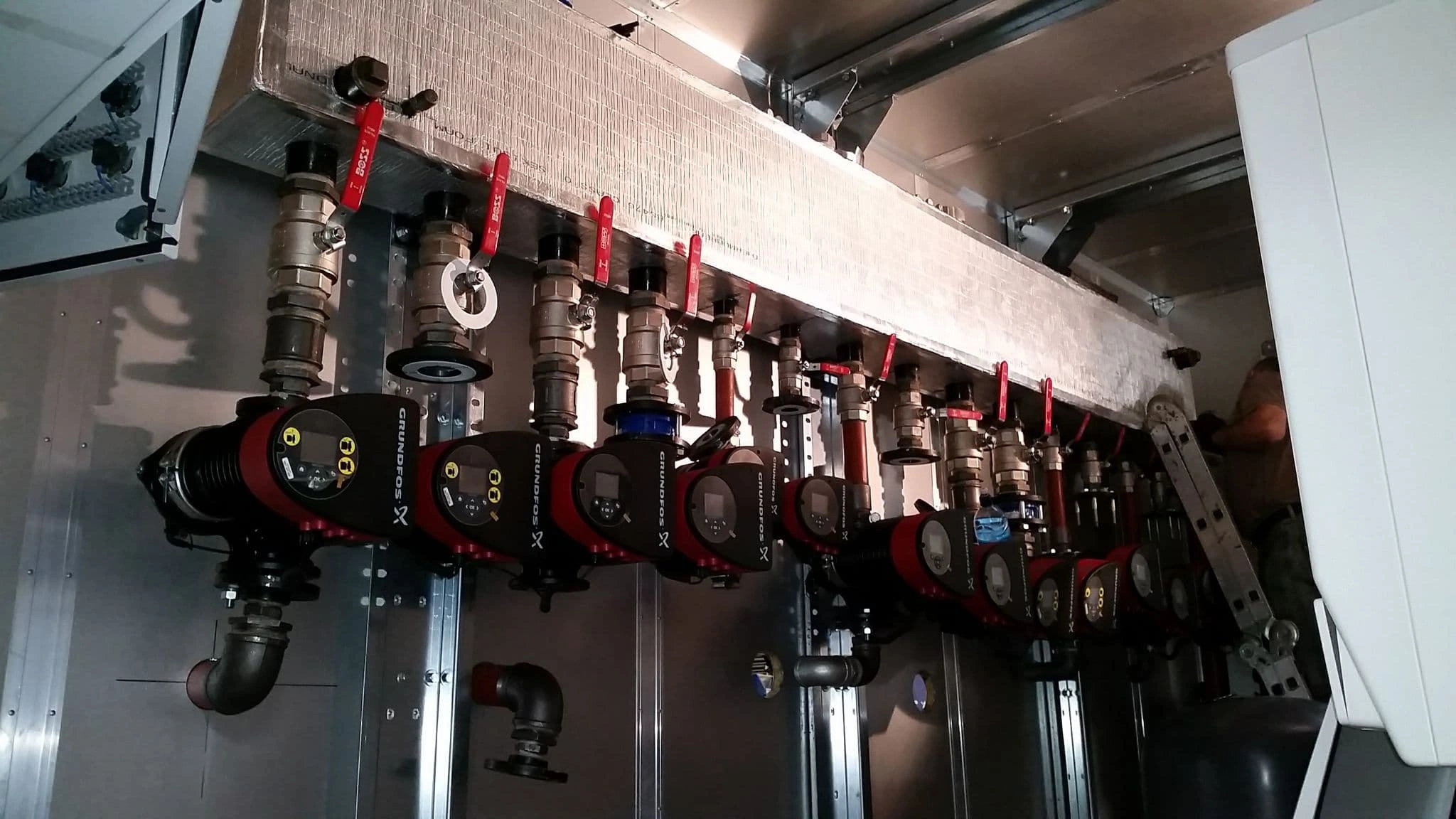

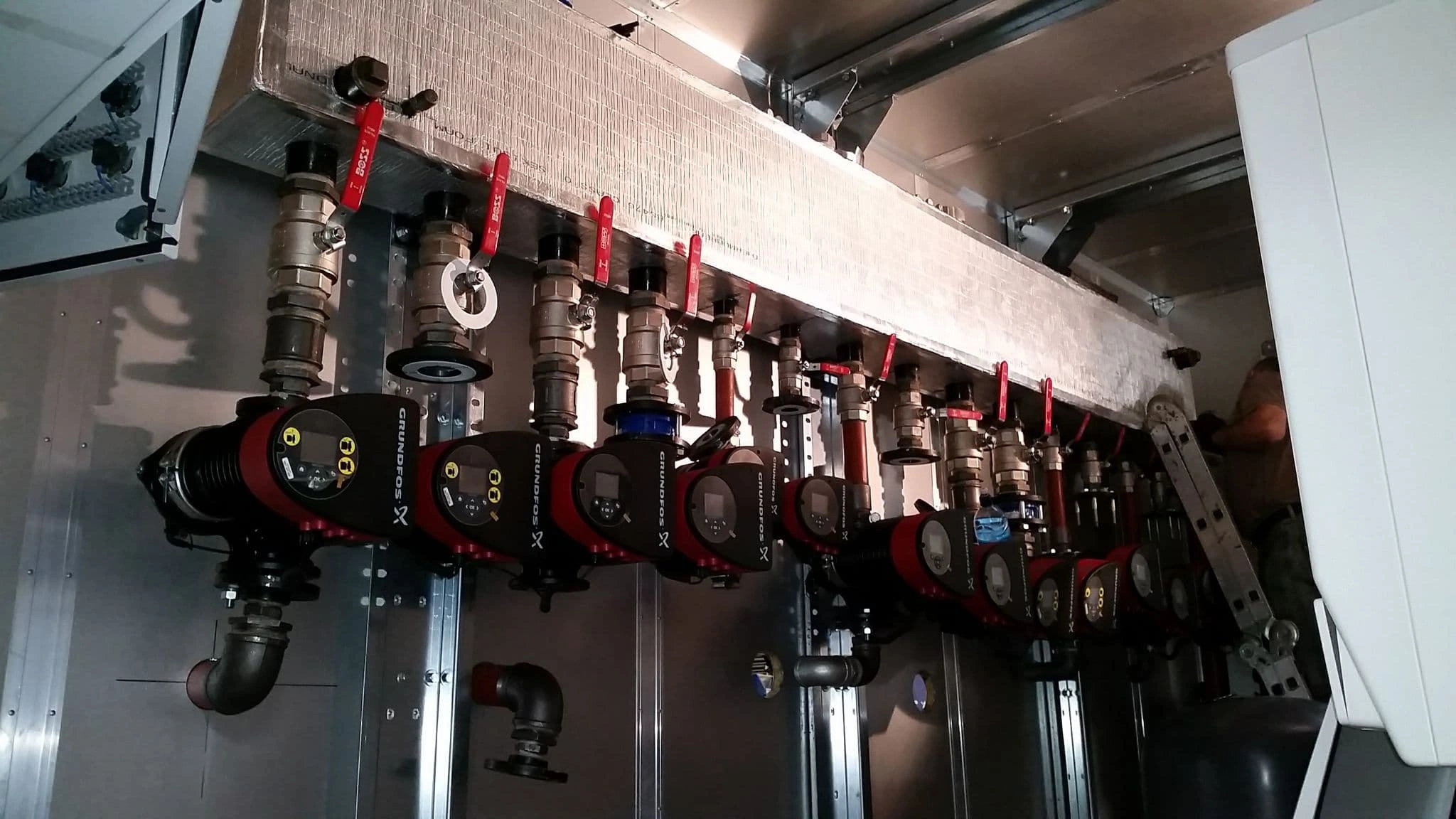

For effective integration and control of a hybrid system, we recommend using solutions like the NRG Zone manifold, which facilitates the interconnection of the heat pump, boiler, and heating zones. Additionally, implementing the NRG Lex 3 with the Hybrid Control Module (HCM) add-on is advised. This control system intelligently manages the transition between the heat pump and boiler, allowing them to operate together or independently, depending on the equipment and the system configuration, for optimal efficiency and system longevity.

Yes, you can add a heat pump to an existing heating system to create a hybrid system. However, there are important considerations to keep in mind. Heat pumps operate at much lower temperatures than traditional boilers, which can affect the performance of existing radiators. When heated by a low-temperature heat pump, these radiators may have a reduced output. To compensate, you might consider installing larger radiators suited for lower temperatures or rely on your existing boiler during colder periods when the heat pump alone may not suffice.

In a hybrid system, the heat pump and boiler mustn’t operate simultaneously unless the operating temperatures have been considered correctly at the design stage due to the significant temperature difference between them. If exposed to the higher-temperature water from the boiler, the heat pump could shut down and even be damaged.

For optimal integration and control of a hybrid system, the use of the NRG Zone manifold is recommended. It effectively interconnects the heat pump, boiler, and heating zones. Additionally, implementing the NRG Lex 3 with the Hybrid Control Module (HCM) add-on is advisable. This setup ensures proper system control, allowing seamless switching between the heat pump and boiler as needed and preventing concurrent operation of both appliances. This approach not only maximizes efficiency but also extends the lifespan of your heating system.

Yes, you can add a solid fuel stove with a back boiler to your heating system, but there are important considerations to address. Solid fuel stoves are categorized as uncontrollable heat sources and must be installed in an open-vented system to prevent pressure buildup. Additionally, it’s vital to include a heat leak radiator in the stove’s gravity circuit to dissipate any excess heat.

If you take the necessary precautions, you can add a stove to an open-vented heating system. In such cases, we recommend using an NRG Zone manifold, which facilitates the stove’s connection with the existing boiler and heating zones, streamlining the system.

However, if you’re adding the stove to a sealed heating system, a particular type of system layout of a prefabricated device is required to transfer heat from the stove’s open-vented system to the sealed system. This device must accommodate the transfer without mixing water or pressures. The NRG Link is designed specifically for this application. It comes pre-plumbed, pre-wired, and pre-insulated for ease of installation. In these scenarios, the NRG Zone manifold is often used with the NRG Link to simplify the system’s design and installation, ensuring a seamless and efficient integration of the solid fuel stove into your heating setup.

Choosing the right size for an NRG Zone manifold depends on the number of connection pairs your system requires. The NRG Zone manifold comes in three standard sizes: NRG Zone 4, NRG Zone 5, and NRG Zone 6. The number in each model name indicates the number of available connection pairs.

For instance, if your system includes one boiler, two radiator zones, and one domestic hot water zone, an NRG Zone 4 would be suitable, as it offers four connection pairs. Similarly, for a system with one heat pump, two underfloor heating manifolds, and two radiator zones, you would require an NRG Zone 5.

Designating your system with at least one pair of spare connections is advisable. This foresight allows for easy expansion, such as adding another heat source or heating zone in the future, perhaps due to building an extension or integrating a renewable energy source. Remove the plugs, and you are ready to add the new zone/appliance.

For larger systems, especially those requiring higher flow rates, the NRG Zone 5 and NRG Zone 6 models are available with 1 1/4” side connections, as opposed to the standard 1” size. These are ideal for systems with larger heat pumps (greater than 14 kW) or boilers (greater than 30 kW).

Additionally, bespoke manifolds can be designed to meet specific requirements for commercial projects or larger installations.

Yes, you can replace a boiler with a heat pump in your existing heating system. However, it’s essential to consider several factors due to the operational differences between these two types of heating systems.

Heat pumps operate at lower temperatures compared to traditional boilers. As a result, your existing radiators may have a reduced heat output when connected to a low-temperature heat pump. To address this, you might consider installing larger radiators designed for lower-temperature operation or switching to underfloor heating, which is more compatible with the lower temperatures of heat pumps.

Another crucial factor is the heat pump’s smaller temperature differential between the flow (outgoing) and return (incoming) water. This characteristic means heat pumps require more water to deliver the same energy as a boiler. Before switching, verify that your existing pipes can handle these higher flow rates. If they aren’t large enough, you may need to replace them. Alternatively, installing a more powerful circulation pump might be sufficient to manage the flow requirements, even with undersized pipes.

When considering this transition, it’s also advisable to evaluate the overall compatibility of your heating system with a heat pump, including insulation levels and the specific heating needs of your property. An energy audit or consultation with a heating specialist can provide valuable insights into the feasibility and adjustments needed to transition from a boiler to a heat pump successfully.

Incorporating individual zone pumps in a heating system, as facilitated by the NRG Zone, offers significant benefits in terms of hydraulic separation and energy efficiency.

Hydraulic Separation: The NRG Zone ensures hydraulic separation between the heat source (like a boiler or heat pump) and each heating zone and between the zones themselves. This separation means the flow rate in one circuit doesn’t impact another. As a result, you can balance each circuit individually, ensuring optimal flow rates for both the heat source and each zone, irrespective of varying demands from different areas.

Reduced Pump Load: Having multiple pumps in a system also helps reduce the overall pump load. In a single-pump system, the pump must overcome the resistance of the heat source and all zones while also managing the entire system’s flow rate. In contrast, with individual zone pumps, each pump is responsible only for its respective zone, handling a lower flow rate and less resistance. Meanwhile, the heat source pump deals with the complete system volume but has only to contend with the resistance of its heat exchanger. This workload distribution lowers the total energy required to run the system compared to a single, larger pump. Consequently, the system becomes more energy-efficient, reducing operational costs.

The unique design of the NRG Zone heating manifold distributes heat efficiently across various zones without requiring actuators. Instead, zone pumps circulate heated water from the top ‘Flow’ chamber to the designated heating zones as needed.

Each zone pump operates independently, enabling precise control over where and when heat circulates. This selective distribution ensures that heat is delivered only to zones that need it, enhancing system efficiency and minimizing energy wastage. By allowing each zone to be heated independently based on demand, the NRG Zone manifold avoids inefficiencies from heating unoccupied or unused areas.

Moreover, the manifold serves as a central control point for the entire heating system, streamlining the management of heat distribution. This centralized approach not only simplifies the system’s operation but also contributes to its overall efficiency, as it reduces the need for complex valve arrangements and actuators typically used in conventional heating systems to regulate flow to different zones.

Using motorised valves for zone control in heating systems presents specific challenges, particularly concerning the efficient operation of modern heating appliances:

Delayed Feedback: Motorised valves can create a delay in system feedback. Modern boilers rely on real-time data, especially the return water temperature, to adjust fuel consumption efficiently. With motorised valves, the boiler receives system feedback only after the heated water has circulated through the zones and returned. This delay can lead to an incorrect assessment of system requirements, potentially causing the boiler to overheat water and consume excess fuel.

Limitation of Automatic Bypass Valves: While an automatic bypass valve might seem like a solution to excessive flow or overheating issues, it can inadvertently signal to the boiler controls that the zones are sufficiently heated, prompting the boiler to reduce its output prematurely.

The NRG Zone manifold addresses these challenges with its fully open bypass design:

Direct Cold Water Return: This design ensures that the coldest system water returns to the boiler. This improvement provides immediate and accurate feedback for the boiler control system, enabling precise fuel consumption adjustments. The effectiveness of this approach remains constant, regardless of how many zones are active.

Boiler Floor Flow Maintenance: The NRG Zone’s design ensures that 100% of the boiler’s flow volume returns consistently, even when multiple zones call for heat. This feature is crucial for protecting the boiler’s heat exchanger and optimizing its efficiency.

Overall System Improvement: By implementing the NRG Zone manifold, systems benefit from improved responsiveness, enhanced efficiency, reduced fuel consumption, and the elimination of flow callback issues. This design is in line with boiler manufacturers’ requirements for optimal operation and efficiency.

In summary, the NRG Zone manifold’s open bypass design overcomes the limitations of traditional zone control systems, ensuring more responsive, efficient, and fuel-effective heating system operation.

The design of the NRG Zone heating manifold’s top chamber, with its large cross-sectional area, is strategically intended to reduce the flow velocity of incoming water. This slower flow allows air entrained within the water to rise. An internal air scoop under the middle top connection captures this air. Equipping this connection with an automatic air vent enhances the manifold’s effectiveness as a de-aeration device. By removing air bubbles from the system, the manifold helps prevent corrosion, enhance overall heating efficiency, and reduce operational noise

The NRG Zone heating manifold contributes to system efficiency by maintaining a clear separation between the hot flow and cooler return water. This design ensures that the heating appliance can consistently draw water at the most efficient temperature. This lower return temperature allows condensing boilers to operate in condensing mode more frequently, thus enhancing their efficiency. Similarly, for heat pumps, this design supports a higher Coefficient of Performance (COP), leading to more effective energy use. The NRG Zone manifold is crucial in maximizing the efficiency of various heating appliances within the system by optimizing the return temperature.

The bypass in the NRG Zone heating manifold is crucial for the functionality of certain heating appliances, particularly heat pumps and low-water content boilers, which require unrestricted flow for proper operation. When zone circulators are de-energised, the bypass does not affect those zones, allowing the heating appliance to maintain circulation without sending heat to those inactive areas. This feature ensures that the system can continue to operate efficiently, with the active circulators directing the flow to the zones that need heating. At the same time, the bypass maintains the overall circulation within the heating appliance itself.

The configuration of NRG Zone allows for a heating appliance to be connected to optimise the flow and return of the water. By connecting the flow from the heating appliance into the top chamber on either the top left or right-hand side and taking the return water back to the heating appliance from the bottom chamber on the corresponding bottom side, a primary loop is created that ensures efficient circulation. This setup is conducive to direct and effective heat exchange, as the hottest water from the appliance enters the system at the top, circulates through the zones, and then the cooled water returns at the bottom and directed to the heating appliance. This method supports a clear path for the heating cycle and benefits system performance and longevity.

The NRG Zone heating manifold and low-loss headers serve different functions, and it’s important to distinguish between the two. While both act as central points in a heating system, a low-loss header is designed to mix the boiler’s flow and return water. This mixing can inadvertently raise the return water temperature to the boiler or heat pump, which might reduce the system’s efficiency or the Coefficient of Performance (COP) of a heat pump.

On the other hand, an NRG Zone heating manifold keeps the hot flow and cooler return water separate. This separation allows the heating appliance to draw from the water at the optimal temperature, thus maximising efficiency. By maintaining a lower return temperature, condensing boilers can operate in condensing mode more often, improving their efficiency, and heat pumps can achieve a higher COP, resulting in better overall energy use.

The V-shaped baffle within the flow chamber is particularly innovative as it deflects the incoming water, creating a uniform flow direction from left to right and allowing for the possibility of connecting two separate heating appliances simultaneously. This is particularly beneficial for systems requiring a larger heating capacity or redundancy purposes, ensuring the flow dynamics work without interference between the two appliances. Connecting appliances on either side adds flexibility to the installation process and allows the tailoring of the system to match the specific layout and requirements of the building it serves.

The NRG Zone heating manifold design caters to all hydronic heating appliances with different operational requirements. The bottom return chamber ensures that the coldest return water is delivered back to optimise the efficiency and cost-effectiveness of condensing boilers or heat pumps, essential for maintaining their high-efficiency operation by enabling the condensing process.

The connections to the middle bypass chamber from both the left and right sides also provide a path for any unused or excess water flow by the zones. This feature is particularly advantageous for non-condensing boilers, such as those used in biomass systems, which require higher return temperatures to operate efficiently and to prevent condensation within the appliance. By facilitating the return of warmer water, the NRG Zone heating manifold enhances the efficiency of these boilers. It ensures their longevity, making the manifold a versatile component suitable for a wide range of heating systems.

The combined effect of the different methods described shows how similar boiler types or high and low-temperature appliances can be interlinked or formed into hybrid systems by simply selecting which return port is most suitable for the system appliances.

The NRG Zone heating manifold’s design provides for flexible and efficient system configurations. The system is primed for optimal efficiency when a heating appliance is connected to one side of the manifold, and zone connections utilise the underside ports for flow and return. The zones draw the hottest water from the top flow chamber, and the cooler water returns to the bottom return chamber, which supports the efficiency of condensing boilers or heat pumps by maintaining low return temperatures.

If an additional zone is required and the opposite side connections are free, these can be utilised for expansion. A circulator can connect to draw water from the top chamber to supply the new zone, with the return connecting to the bottom side return connection. This setup ensures that all zones have access to the hottest water for heating while maintaining the return temperatures conducive to high-efficiency heating appliance operation. This modular design makes the NRG Zone heating manifold highly adaptable to practically all system demands and configurations.

The NRG Zone heating manifold is designed for versatility, managing water flow and return in heating zones and appliances and accommodating various system enhancements. You can also use the manifold’s spare connections for integrating additional components, such as system filling, expansion vessels, or pressure and temperature gauges. This flexibility enhances the manifold’s functionality and provides more comprehensive system monitoring. Additionally, its pre-assembled configuration simplifies installation, offering a quicker and more cost-effective solution than traditional fitting assemblies, which may not always provide optimal performance.

The NRG Zone heating manifold is critical as it forms the system’s neutral point, where static and dynamic pressures are balanced. This balance makes it an ideal location for circulators to draw water, ensuring steady flow throughout the system. As water circulates through zones or the boiler and returns to the manifold, the primary circuit of the NRG Zone compensates for the suction force created by zone circulators, preventing voids and maintaining consistent flow.

Moreover, the NRG Zone’s ability to maintain stable static pressure makes it an optimal site for connecting expansion vessels, open expansion pipes, or the system’s cold feed. This stable environment is essential for preventing pressure fluctuations that could negatively impact the system. It also makes the NRG Zone an ideal connection point for safety and pressure-related sensors, enhancing the system’s safety and efficiency. Centralizing these components at the neutral point simplifies monitoring and maintenance, ensuring the system operates optimally.

Additionally, as the industry-recommended location for connecting vents and system cold feeds, the NRG Zone’s open chamber access allows for the neutralization of excess or reduced water pressures. This design prevents differential pressures that could lead to issues like induced air or pitching over the header tank in open-system configurations.

The prefabricated NRG Zone heating manifold significantly impacts the heating industry by addressing a critical challenge: the shortage of skilled installers. Its design, which maintains consistent operational principles across various scales of heating systems, from small domestic to large commercial installations, simplifies the learning curve for installers. This uniformity in learning and application is a significant advantage, as it allows installers to master one system and apply their knowledge across different installation sizes, with the primary variation being the NRG Zone unit’s size.

This streamlined training approach can lead to more efficient training programs, enabling installers to become proficient more quickly. As a result, the industry can more rapidly address the skilled labour shortage, especially in the face of increasingly complex heating systems.

Furthermore, this uniformity in design and operation enhances the quality of installations and maintenance services. Installers can provide more consistent and comprehensive services by focusing on a singular, adaptable system. This easy-to-use technology accelerates the rate at which new installers can be field-ready and raises the overall standard of service in the heating industry. The NRG Zone manifold, therefore, represents a significant step towards simplifying complex heating system installations and maintenance, benefiting both the industry and its customers.

The pre-assembled and simplified design of the NRG Zone heating manifold brings significant advantages in reliability and maintenance. Its lack of moving parts and actuators reduces the potential for mechanical failures, enhancing the system’s overall reliability. This aspect is particularly valuable in complex heating installations where more parts typically mean a higher chance of breakdowns.

In terms of maintenance, the simplicity inherent in the NRG Zone’s design means it is less susceptible to common issues that require professional attention. This reduced maintenance demand is highly beneficial in the heating industry, where there is a current shortage of skilled labour. Heating professionals can allocate less time to repairs and more to installation and other essential tasks, potentially easing the labour shortage by increasing the number of installations that can be managed within a given timeframe.

Furthermore, the shift towards less maintenance-intensive systems like the NRG Zone allows more efficient utilization of skilled labour in the heating industry. This efficiency is beneficial in addressing labour shortages and contributes to overall trade efficiency, making the NRG Zone a key component in streamlining and optimizing heating system installation.

The flexibility of the NRG Zone heating manifold to function as a heat collector in larger, centralised boiler arrangements is a significant advantage. In complex multi-boiler, multi-zone systems, reversing the connections underneath larger NRG Zone units to collect heat from multiple boilers while using the side connections to distribute heat to other areas streamlines the entire system’s design and installation.

This feature simplifies the traditionally complex process of managing and sequencing multiple boilers, making the system more efficient and easier to manage. It also reduces the likelihood of errors and failures, enhancing the system’s overall reliability. By centralising heat collection and distribution in this way, the NRG Zone manifold effectively acts as a hub in the heating system, efficiently coordinating the flow of heat from multiple sources to multiple zoned areas.

The NRG Zone’s streamlined approach to system layout significantly reduces the time required for design and installation. System designers can create complex heating solutions more quickly and efficiently, as they no longer need to account for the intricate piping and control systems traditionally required for multi-boiler installations. This unique strategy makes the design process faster and more cost-effective, allowing designers to focus on optimising system performance rather than managing complexity.

Overall, the NRG Zone’s adaptability in handling simple and complex heating system requirements and its ease of installation and reliability represents a substantial improvement in its design and implementation. This advancement is particularly valuable in an industry where time, efficiency, and reliability are key factors in both design and operation.

Features of NRG Zone Manifold

Benefits of NRG Zone Manifold

In summary, the NRG Zone heating manifold brings high efficiency, reliability, and versatility to heating system design and implementation. Its unique features make it an asset in small-scale and large, complex installations, streamlining processes and significantly reducing the time and expertise required for installation and maintenance. This manifold represents a substantial advancement in heating system technology, particularly beneficial in the current landscape of the heating industry.

Two optimal heating methods for pumped-controlled hydronic system design are the primary-secondary (P-S) pumping method and the NRG Zone method. The following is a comparative breakdown of the features of both methods:

Primary-Secondary (P-S) Pumping Method

NRG Zone Method

Summary

While the primary-secondary-zone approach in hydronic heating systems offers advantages like energy savings and reduced pressures, it has limitations regarding controllability and adaptability to system changes. The NRG Zone method, however, retains the benefits of the P-S approach but improves upon its weaknesses. By ensuring equal access to high-temperature flow for each zone and hydronically separating them, the NRG Zone method enhances system efficiency, controllability, and adaptability, significantly improving hydronic heating system design.